Guitarists and musicians worldwide have relied on BOSS pedals for decades, and seem to keep coming back for more. The Japanese manufacturer is one of the undisputed titans of the stompbox world. Credited with bringing guitar pedals to the masses, they pioneered the compact effects format and remain industry leaders to this day.

Aside from their compact designs and colourful legacy, they’re known for one other crucial thing: they’re borderline-invincible. Let’s take a look at how BOSS earned this reputation; why do their pedals last so long, and how much can they really handle?

The Casing

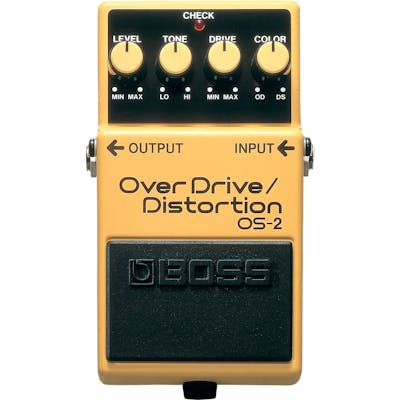

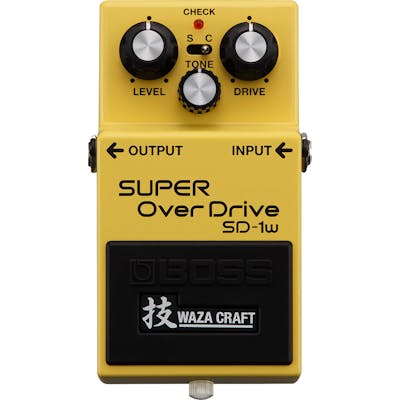

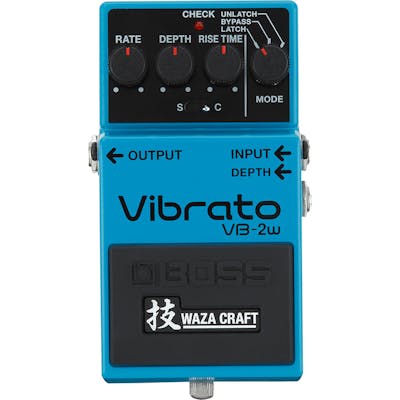

We all know what BOSS pedals look like. They’re arguably one of the few bits of guitar gear – alongside Fender Strats and Marshall amps – that might just be recognisable by members of the general public.

Part of the reason BOSS pedals are so recognisable is that their signature compact casing has remained the same since 1977. That’s over 4 decades. Those tough angles are built like armour plating; it’ll take quite a lot of force to do any serious damage.

In addition, the position of the footswitch was designed in such a way that it prevented your foot from reaching the rest of the controls. That means that you won’t stomp on the knobs and extra buttons when you’re switching, so there’s no risk of damaging the control panel. Smart, eh?

The Switch

Similarly, the internals of the switching system were designed back in 1977 and haven’t changed since. They were originally built to eliminate pops and clicks – so they were noise-free from the get-go.

According to numerous tests conducted on their footswitch design, you can stomp over 100,000 times and it’ll still work perfectly. We reckon that might just outlive your favourite pair of shoes.

Extensive Testing

Naturally, BOSS take the time to make sure that their pedals are gig-ready and working perfectly before being shipped from the factory. We consulted BOSS about their testing process, and we weren’t disappointed. Here’s a taste of what their stompboxes go through during QC:

- Drop tests – all pedals are dropped from a range of heights to ensure they can withstand impacts of all magnitudes. From hold luggage to flights of stairs, there’s nothing they can’t handle!

- Humidity tests – all pedals are tested from 0% to 100% humidity. This not only ensures that they survive, but that they continue to perform as expected, regardless of conditions.

- Temperature test – as above, but with a broad range of temperatures. Your BOSS pedal will perform just as well in your isolated Arctic Studio as it will on stage at the heights of the American summer!

- Shock tests – it’s all starting to sound a bit cruel, isn’t it? Yep, BOSS shock their pedals to ensure that they’ll withstand electrical failure and power surges.

It’s worth noting that BOSS and their parent company Roland put all of their products through this rigorous testing routine. Tough cookies indeed!

Time-tested Components

It might go without saying that BOSS only use top-quality components for their pedals, which contributes to their bonkers longevity. In addition, every detail is considered and scrutinised; the order of components, the space that they require, and so on.

This sometimes extends to BOSS designing their own technology from scratch. A good example of this is their WL wireless systems; to facilitate the reliability and performance of their WL design, they feature proprietary wireless technology. They aren’t afraid to work from the ground up to ensure that they get it right – and it shows!

How tough are BOSS pedals?

Spend a bit of time on Google, and you’ll quickly see that BOSS pedals’ toughness is well documented.

Fans have done just about everything to their BOSS pedals, and for the most part, they just keep coming back. This includes submerging them, running them over, using them as baseballs…

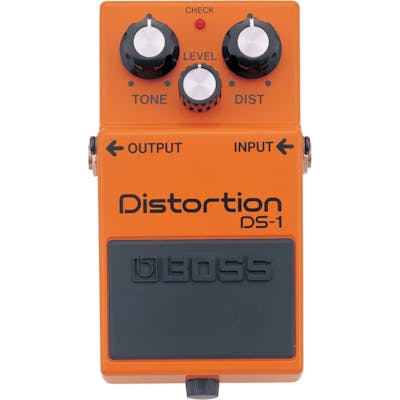

…and our personal favourite, freezing them. Here’s Simon The Magpie’s frozen DS-1 experiment:

.JPG?w=400&h=400&&fit=fill&bg=FFFFFF)

.JPG?w=400&h=400&&fit=fill&bg=FFFFFF)

.JPG?w=400&h=400&&fit=fill&bg=FFFFFF)

.JPG?w=400&h=400&&fit=fill&bg=FFFFFF)

.JPG?w=400&h=400&&fit=fill&bg=FFFFFF)

Responses & Questions