- Bigsby Yoga

- The problem with the Bigsby Trem – In a Nutshell

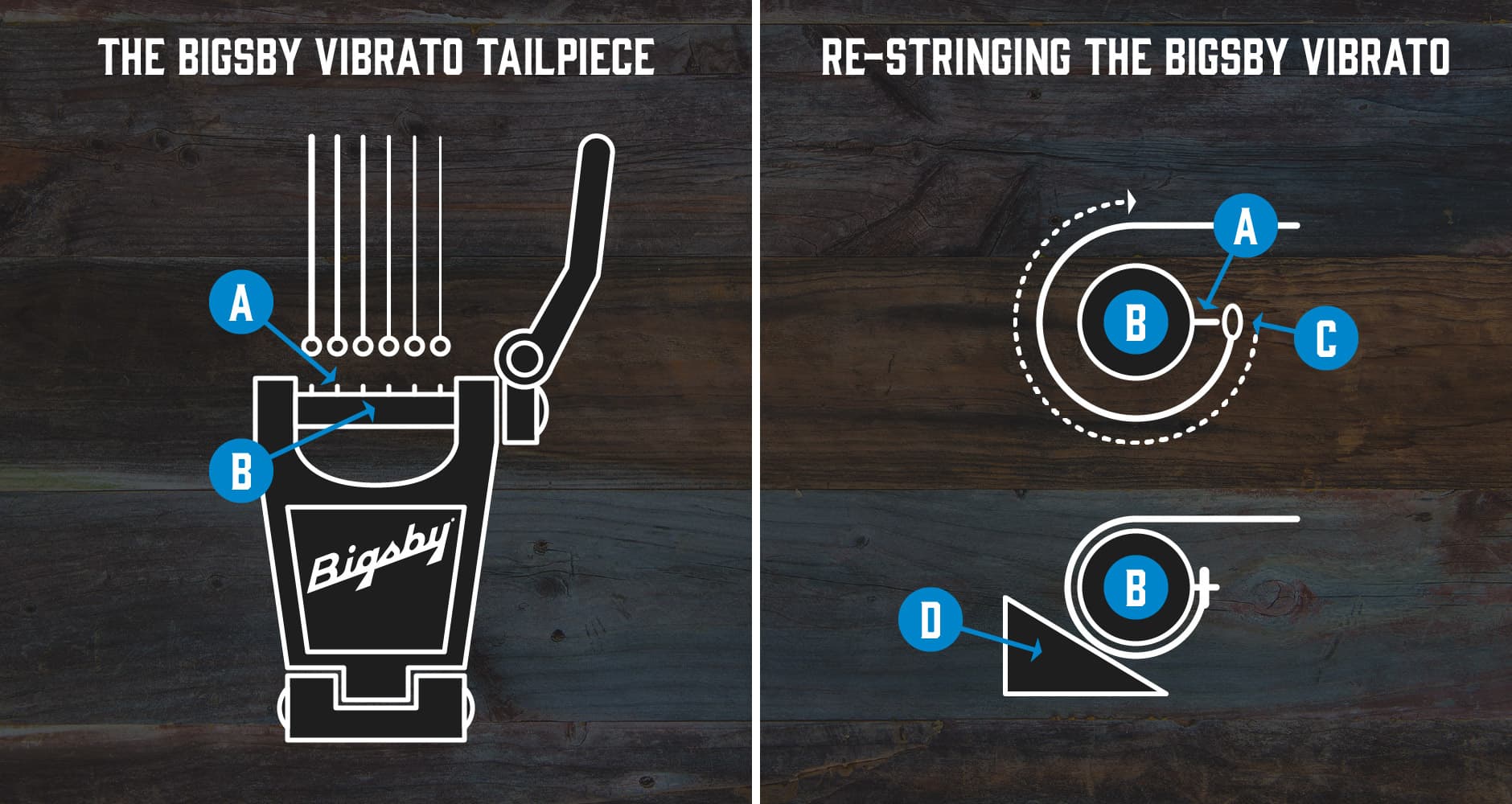

- The Official Bigsby Guide To Re-Stringing

- The Capo Trick

- The Bigsby vs. Floyd Rose challenge on Andertons TV

- Alternative Bigsby Re-stringing methods

- What’s the difference between Bigsby B3, Bigsby B5, Bigsby B7 and more?

- Conclusion

Re-stringing a guitar is generally an easy process, which gets easier the more you do. At first, it’s a challenge, and then you start challenging yourself to do it faster.

Bigsby Yoga

What looks like a fairly simple tremolo system can actually cause a bit of a headache the first time you come around to re-stringing your Bigsby-equipped electric guitar. I know it did for me the first time I tried to do it. It’s safe to say I needed a few extra arms to get it right, because the ball-end of the string just wouldn’t stay hooked to the Bigsby. What a mess.

But, after doing it a few more times, I wanted to share some advice to make life easier for you when you want to re-string that Bigsby.

Disclaimer: This is just a basic how-to guide. If you aren’t confident with doing it yourself, then book your guitar in for a setup or for a re-string with your local tech. Always be careful when using string clippers and make sure to release the string tension before clipping the string.

The problem with the Bigsby Trem – In a Nutshell

When stringing a string-thru body guitar, or even a classic tremolo style body, the string catches on the bridge-piece, leaving both of your hands free to focus on pulling the string through the machinehead and winding it onto the string post.

A Bigsby is slightly different, because you have to hook the ball-end over a pin extruding from the Bigsby tailpiece. And the trick is making sure the ball-end stays hooked onto the small pole-piece while you do the work on the machinehead post.

The second any tension is lost, the string will fall off and you’ll need to start again.

Bigbsy themselves recommend getting a small foam wedge to keep the ball-end in place every time you do another string.

The Official Bigsby Guide To Re-Stringing

You’ll need:

- Wirecutters – to clip strings

- Needle Nose Pliers – to crimp the string

Here’s the step-by-step guide:

- Crimp the string at a 45° angle next to the ball end (A).

- Feed the string underneath, around and over the axle (B).

- Place the ball end of the string onto the axle pin (C), keeping tension on the string to hold the ball in place.

- Push a foam wedge (D) into the space under the axle to keep the string in place on the pin while winding.

- Wind the string onto the tuning machine, tune to pitch and remove the foam wedge.

The Capo Trick

You’ll need:

- Wirecutters

- Needle Nose Pliers

- A Capo

Another good way to hold the tension of the string down while you wind it around the post is by simply using a capo!

You’ll still need to crimp the string to feed it onto the rotating shaft of the Bigsby trem. Feed the string underneath the rotating shaft and put the ball-end onto the axle pin as normal.

Then, instead of using the foam wedge to hold the string in place, you can pull the tension of the string and place the capo onto the 9th fret. Hey, presto!

This will hold the string in place while you measure how much string you’ll need to wind around the post. The best thing about this is you can take your sweet time winding it around the post. With the capo on, you could even leave the guitar and make a cup of tea!

From there you can just thread the machinehead post and string as normal.

Responses & Questions